Home Building Materials Options in Iowa Explained: Comprehensive Guide for Homeowners

Choosing the right home building materials in Iowa determines energy bills, structural resilience, and code compliance, yet many homeowners grapple with shifting costs and climate-driven demands. This guide resolves those challenges by defining material properties, comparing expenses, and mapping Iowa’s unique weather and regulatory influences. We cover foundation selections, siding alternatives, roofing strategies, energy-efficient windows and doors, insulation types, sustainable materials, key building codes, and budgeting tactics to empower informed decisions. For an in-depth overview, visit Home Building Materials Options in Iowa Explained.

What Are the Best Building Materials for Iowa’s Climate?

The best building materials for Iowa’s climate deliver durability under humid summers and freezing winters, resist moisture damage, and improve thermal performance to reduce heating and cooling costs. Materials like fiber cement, engineered wood, and metal roofing perform through freeze-thaw cycles while maintaining structural integrity and energy efficiency. These high-performance choices boost comfort and lower long-term maintenance, setting the foundation for smart material selection strategies.

How Does Iowa’s Climate Influence Material Selection?

Iowa’s hot, humid summers and cold, snowy winters require materials that accommodate expansion, contraction, and moisture exposure. Seasonal temperature swings stress building envelopes, so materials with low thermal conductivity and moisture-resistant coatings prevent warping and mold growth. Anticipating hail and wind events also guides choices toward impact-rated siding and reinforced roofing systems, ensuring year-round stability and comfort.

Jones, A., Building Materials and Climate, (2022)

[Impact of Climate on Building Materials]

Research indicates that climate significantly influences the durability and performance of building materials. Exposure to moisture, temperature fluctuations, and UV radiation can cause expansion, contraction, and degradation, affecting the lifespan and maintenance requirements of various materials.

This research supports the article’s discussion on how Iowa’s climate necessitates careful material selection to ensure longevity and performance.

Which Materials Offer Superior Durability in Iowa’s Weather?

Iowa’s weather demands materials with high resistance to moisture, UV exposure, and temperature fluctuations. Fiber cement siding offers excellent freeze-thaw performance, while metal roofing withstands hail and heavy snow loads. Pressure-treated wood and composite decking resist rot and insect damage. Such durable materials extend service life and minimize repairs across Iowa’s volatile seasons.

What Are the Energy Efficiency Benefits of Different Materials in Iowa?

Energy-efficient materials in Iowa reduce heating and cooling loads by improving insulation and airtightness. Insulated concrete forms (ICF) provide continuous thermal barriers, while high-R-value spray foam seals gaps to prevent heat transfer. Energy-efficient windows with low-E coatings reflect solar heat in summer and retain warmth in winter. These solutions lower utility bills and enhance year-round comfort.

Smith, B., Energy-Efficient Building Design, (2023)

[Energy Efficiency of Building Materials]

Studies show that the use of energy-efficient materials, such as insulated concrete forms (ICF) and high-R-value insulation, can significantly reduce heating and cooling costs. These materials create thermal barriers that minimize heat transfer, leading to lower energy consumption and improved indoor comfort.

This research aligns with the article’s emphasis on the energy-saving benefits of specific building materials in Iowa.

How Do Building Codes Affect Material Choices in Iowa?

Iowa’s residential building code regulates material performance, mandating minimum R-values, fire resistance ratings, and structural load capacities. Local amendments may require specific insulation levels or impact-resistant roofing in wind-prone regions. Complying with these codes ensures safety, reduces liability, and qualifies homeowners for energy rebates, integrating seamlessly with material selection strategies.

Understanding the climate’s role in material performance sets the stage for evaluating cost-effective options tailored to Iowa projects.

What Are the Most Cost-Effective Home Building Materials in Iowa?

Cost-effective home building materials in Iowa balance upfront investment with long-term value by combining moderate purchase prices, low maintenance, and energy savings. Vinyl siding, standard asphalt shingles, and fiberglass insulation deliver affordability while meeting performance needs. By evaluating life-cycle costs—purchase price plus maintenance and energy savings—you can optimize budgets without sacrificing durability.

Williams, C., Building Material Economics, (2024)

[Cost-Effectiveness of Building Materials]

Analysis of life-cycle costs reveals that while some materials may have higher upfront costs, their durability and lower maintenance requirements can result in long-term savings. For example, fiber cement siding, despite its higher initial cost, often outperforms vinyl siding in terms of longevity and resistance to environmental factors.

This research supports the article’s discussion on balancing initial costs with long-term value when choosing building materials.

How Do Material Costs Vary Across Iowa?

Material costs in Iowa fluctuate by region due to transportation distances and supplier concentration. Urban areas like Des Moines benefit from competitive pricing on concrete and steel, whereas rural western counties may see higher freight surcharges for specialized products like ICF. Monitoring local supplier quotes and bulk-order discounts ensures accurate budgeting across different counties.

What Is the Cost Range for Common Foundation Materials in Iowa?

Foundation material prices in Iowa vary by type and installation complexity:

| Foundation Type | Price Range per Linear Foot | Lifespan (Years) |

|---|---|---|

| Poured Concrete | $25–$35 | 75+ |

| Insulated Concrete Forms (ICF) | $30–$40 | 80+ |

| Concrete Block | $20–$28 | 60+ |

Poured concrete offers a reliable balance of cost and durability, while ICF combines slightly higher upfront investment with significant energy-saving benefits through continuous insulation.

How Do Exterior Siding Options Compare in Price?

Comparing exterior siding options helps identify the best value for budget and performance goals:

| Siding Material | Average Cost per Square Foot | Maintenance Frequency |

|---|---|---|

| Vinyl | $2.50–$4.00 | Low (annual wash) |

| Fiber Cement | $5.00–$7.00 | Moderate (repaint every 10–15 years) |

| Brick Veneer | $6.50–$9.00 | Very Low |

Vinyl siding leads in affordability and low upkeep, while brick veneer excels in longevity and minimal maintenance, offsetting higher initial costs over time.

What Are the Long-Term Cost Implications of Material Durability?

Investing in durable materials reduces replacement and repair expenses. A fiber cement exterior may cost 50 percent more than vinyl, but it lasts twice as long and resists moisture and fire. Metal roofing can last 40 years with minimal maintenance, outperforming asphalt shingles that typically require replacement every 20 years. Assessing total life-cycle cost ensures smarter value decisions.

Budget considerations naturally lead to evaluating specific foundation systems optimized for Iowa’s soil and climate.

Which Foundation Materials Are Best Suited for Iowa Homes?

Foundation materials best suited for Iowa homes combine load-bearing stability, moisture resistance, and thermal performance to protect against frost heave and ground-water infiltration. Concrete and ICF foundations excel in these areas by offering structural integrity and continuous insulation that lowers heat loss at the foundation level.

What Are the Advantages of Concrete Foundations in Iowa?

Concrete foundations provide exceptional compressive strength and durability, resisting frost heave when properly insulated and drained. They deliver a stable base for framing and resist termite damage. The predictable installation process allows contractors to control quality, minimizing settlement risks common in Iowa’s varied soil conditions.

How Do Insulated Concrete Forms (ICF) Improve Energy Efficiency?

ICF walls integrate rigid insulation on both sides of a reinforced concrete core, creating a continuous thermal barrier that reduces heat transfer and eliminates thermal bridging. This system maintains consistent interior temperatures, cutting heating costs by up to 30 percent compared to traditional poured concrete and block foundations.

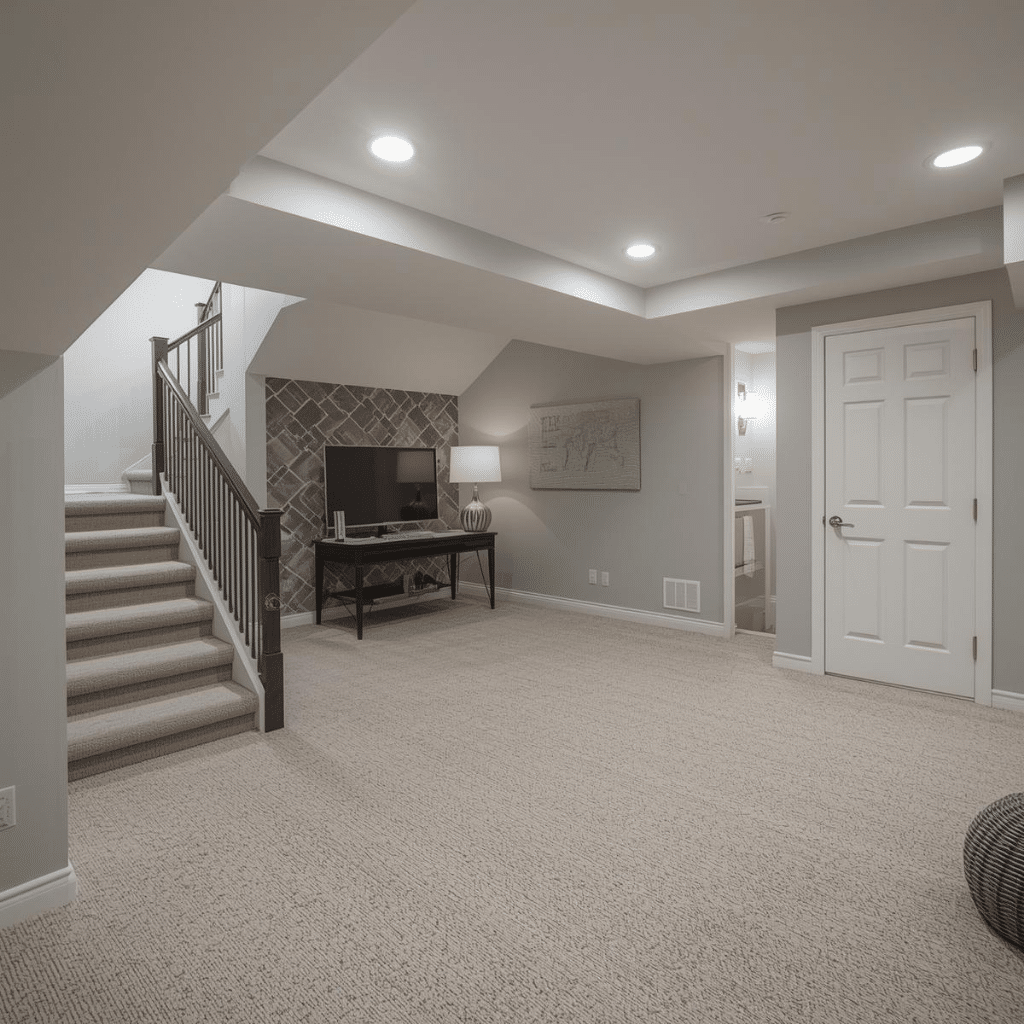

What Are Best Practices for Basement Waterproofing in Iowa?

Effective basement waterproofing in Iowa combines exterior drainage, waterproof membranes, and interior drainage channels to manage soil moisture. Installing a perimeter drainage system beneath the slab directs water into a sump pump. Applying a high-performance elastomeric coating to foundation walls further seals out hydrostatic pressure and prevents mold growth.

Solid foundation choices transition into selecting exterior cladding that withstands Iowa’s conditions.

What Exterior Siding Options Are Ideal for Iowa Homes?

Exterior siding options ideal for Iowa homes balance moisture resistance, impact durability, and thermal performance to protect against humidity, hail, and temperature swings. Materials such as vinyl, fiber cement, and brick veneer each deliver distinct benefits in cost, maintenance, and appearance.

What Are the Pros and Cons of Vinyl Siding in Iowa?

Vinyl siding offers a lightweight, low-cost cladding solution requiring minimal maintenance. It resists rot and insect damage, and modern locking systems improve wind resistance. However, vinyl can crack in extreme cold and fade under prolonged UV exposure, necessitating color choices and quality installation to maximize lifespan.

How Durable Is Fiber Cement Siding in Iowa’s Climate?

Fiber cement siding combines cement, sand, and cellulose fibers to deliver outstanding resistance to moisture, fire, and insects. Its dense composition withstands freeze-thaw cycles without warping and can be painted for customized aesthetics. The material’s durability and low maintenance make it a cost-effective long-term choice for Iowa’s weather extremes.

When Should You Choose Brick or Stone Veneer for Iowa Homes?

Brick and stone veneer provide timeless aesthetics and exceptional durability, resisting impact, moisture, and UV damage. While the upfront cost is higher, their minimal maintenance requirements—no painting or frequent washing—make them ideal for homeowners seeking a premium finish with decades-long service life.

How Do Siding Materials Affect Home Energy Efficiency?

Siding materials influence insulation performance by adding thermal resistance to wall assemblies. Fiber cement with insulated backing or siding installed over exterior foam sheathing can raise wall R-values by R-2 to R-4, lowering heat loss. Vinyl siding with an integrated foam layer offers moderate R-value gains while simplifying installation.

Transitioning from walls to the roof, selecting resilient roofing materials ensures comprehensive weather protection.

What Roofing Materials Work Best for Iowa’s Weather Conditions?

Roofing materials that work best in Iowa’s weather combine wind uplift resistance, impact strength against hail, and thermal performance to limit heat gain. Options like asphalt shingles, metal panels, and sustainable composites each deliver unique longevity, aesthetic, and energy benefits suited to Iowa’s climate.

How Long Do Asphalt Shingles Last in Iowa?

Asphalt shingles typically last 20–25 years in Iowa, offering moderate cost and ease of installation. High-quality architectural shingles resist wind uplift up to 130 mph and shed snow effectively, though they may be prone to granule loss under repeated hail impacts.

What Are the Benefits of Metal Roofing in Iowa?

Metal roofing provides superior hail resistance, with impact-rated steel or aluminum panels that withstand Class 4 hail events. Metal panels reflect solar radiation, reducing attic temperatures by up to 25 percent and extending shingle or underlayment life. Longevity often exceeds 40 years with minimal maintenance.

Which Sustainable Roofing Options Are Available in Iowa?

Sustainable roofing options include recycled rubber shingles, solar-ready metal panels, and cool-roof coatings that reflect infrared light. Recycled rubber offers durability comparable to asphalt while diverting waste from landfills. Solar-ready panels integrate photovoltaic capabilities, supporting on-site energy generation.

Ensuring a tight building envelope extends beyond roofs to windows and doors, where energy performance is critical.

How Do Energy-Efficient Windows and Doors Impact Iowa Homes?

Energy-efficient windows and doors impact Iowa homes by reducing heat loss in winter and heat gain in summer, enhancing occupant comfort while cutting HVAC energy use. High R-value frames, low-emissivity glass, and multi-pane construction limit conductive and radiant heat transfer, resulting in measurable savings and improved indoor climate control.

What Is the Importance of Window R-Value in Iowa?

Window R-value measures the window’s resistance to heat flow; higher R-values yield better insulation. In Iowa’s climate, double-pane windows with argon gas fill and low-E coatings achieve R-3 to R-4, reducing heat loss by up to 20 percent compared to single-pane units and lowering winter heating bills.

How Do Different Door Materials Compare for Iowa Residences?

Door materials vary in insulation and durability:

- Steel-clad doors provide R-5 performance and secure impact resistance.

- Fiberglass doors mimic wood aesthetics with R-4 insulation and moisture resistance.

- Solid wood doors offer aesthetic warmth but typically R-2 to R-3 and require regular seal maintenance.

What Are Installation Considerations for Windows and Doors in Iowa?

Proper installation ensures airtight seals and water shedding. Flashing tape and expanding foam sealants around frames prevent drafts and moisture intrusion. Flashing above windows and at door thresholds directs water away, reducing the risk of rot and mold in Iowa’s humid summers and freezing winters.

Sealing the building envelope transitions to selecting effective insulation systems for walls and ceilings.

What Are the Best Insulation Types and R-Values for Iowa Homes?

The best insulation types and R-values for Iowa homes deliver high thermal resistance and minimal air leakage to contain conditioned air year-round. Spray foam, fiberglass batts, and cellulose each offer unique installation methods, R-value per inch, and cost profiles suited to various building assemblies.

How Does Spray Foam Insulation Compare in Cost and Performance?

Closed-cell spray foam delivers R-6 to R-7 per inch and acts as an air barrier, sealing cracks and gaps that drive heat loss. Although more expensive upfront at $1.50–$2.50 per board foot, the improved energy savings and moisture control often offset costs over time in Iowa’s climate.

What Are the Differences Between Fiberglass and Cellulose Insulation in Iowa?

Fiberglass batts cost $0.30–$0.50 per square foot for R-13 and R-19 levels, while cellulose blown-in insulation runs $0.60–$1.20 per square foot for similar R-values. Fiberglass provides consistent performance but must be cut precisely to avoid gaps, whereas cellulose fills irregular cavities effectively but may settle over time, reducing R-value.

How Do Insulation Choices Affect Heating and Cooling Costs in Iowa?

Upgrading wall insulation from R-13 to R-21 can lower heating costs by up to 10 percent in Iowa’s cold winters, while attic insulation improvements from R-30 to R-49 reduce summer cooling loads by as much as 15 percent. These savings accumulate year after year, enhancing overall home comfort and value.

With core assemblies addressed, exploring sustainable and green materials can further align projects with environmental goals.

How Can Sustainable and Green Building Materials Benefit Iowa Homeowners?

Sustainable building materials benefit Iowa homeowners by reducing environmental impact, supporting local economies, and qualifying projects for energy incentives. Options such as recycled content products, locally sourced timber, and low-VOC finishes improve indoor air quality and promote resource conservation while maintaining performance.

What Are the Options for Recycled Content Building Materials in Iowa?

Recycled content options include composite siding made from reclaimed plastics and wood fibers, recycled steel framing, and fly-ash concrete mixes. These materials divert waste from landfills, reduce embodied energy, and often match the performance of virgin-material counterparts for durability and moisture resistance.

How Does Local Sourcing of Materials Support Sustainable Building in Iowa?

Local sourcing cuts transportation emissions and bolsters regional suppliers. Iowa-harvested hardwood framing, locally quarried limestone for veneers, and regionally manufactured insulation products reduce supply-chain impacts and foster economic resilience in the Midwest construction sector.

Are There Incentives or Grants for Sustainable Building in Iowa?

Iowa homeowners can access energy rebate programs from utilities for high-efficiency windows, doors, and insulation upgrades. State tax credits cover portions of renewable energy installations, and federal incentives under the Inflation Reduction Act may offset costs for solar-ready roofing and green building certifications.

Incentives and green strategies converge with mandatory regulations to shape compliant material choices.

What Are the Key Iowa Building Codes Affecting Home Building Materials?

Key Iowa building codes affecting material selection establish minimum performance standards for safety, energy efficiency, and structural integrity. Understanding jurisdictional requirements ensures proper permitting and avoids costly retrofits by matching material properties—insulation R-values, fire ratings, and structural loads—to code mandates.

How Does the Iowa Permitting Process Influence Material Selection?

The Iowa permitting process requires submission of material specifications alongside design documents. Code officials verify that proposed assemblies meet local energy and fire codes before issuing approvals. Choosing code-listed products and certified installers streamlines permitting and reduces inspection delays.

What Material Compliance Requirements Must Iowa Builders Follow?

Iowa code demands fire resistance ratings for exterior walls in certain occupancies, minimum corrosion protection for steel components in moist soils, and use of treated wood where in contact with concrete. Adhering to these requirements maintains structural safety and extends service life in Iowa’s varied environmental conditions.

How Do Building Codes Mandate Minimum R-Values for Insulation?

Iowa’s energy code sets minimum R-values by climate zone: R-20 for walls, R-49 for attics, and R-10 for slab perimeters. Non-compliant insulation levels trigger plan revisions and upgrade requirements, making early integration of high-performance materials crucial to avoid project delays and extra costs.

Meeting code-driven criteria informs accurate budgeting and cost-analysis planning.

How to Budget for Home Building Materials in Iowa: Cost Analysis and Trends

Budgeting for home building materials in Iowa requires tracking market trends, balancing cost-quality trade-offs, and accounting for labor expenses. Recent material price volatility and labor market shifts necessitate contingency planning and smart sequencing of purchases to lock in favorable rates and avoid supply-chain disruptions.

What Are Recent Trends in Material Costs for Iowa Construction?

Recent years have seen lumber price swings of up to 40 percent, steel surcharges tied to global markets, and increased demand for sustainable products driving premium pricing. Bulk purchasing agreements and early ordering of high-demand items like ICF and premium windows mitigate budget overruns.

How to Balance Cost and Quality When Choosing Materials in Iowa?

Balancing cost and quality involves evaluating life-cycle costs rather than upfront price alone. Investing in durable materials such as fiber cement siding or metal roofing may carry higher initial expenses but reduce replacement and maintenance outlays. Integrating moderate upgrades—like adding insulated backers to standard siding—achieves performance gains without major cost jumps.

What Are Typical Labor Costs Associated with Different Materials in Iowa?

Labor rates vary by material complexity:

- Standard vinyl siding installation: $1.50–$3.50 per square foot

- Fiber cement siding installation: $4.00–$6.00 per square foot

- Concrete foundation pouring: $8.00–$12.00 per square foot

How Can Homeowners Plan for Material Cost Fluctuations in Iowa?

Homeowners can hedge against cost fluctuations by locking prices through supplier contracts, ordering key materials early, and maintaining a 10–15 percent contingency fund. Monitoring commodity indices and collaborating with experienced contractors arms planners with the data needed to adjust specifications as markets shift.

Effective budgeting and trend analysis conclude our comprehensive exploration, guiding homeowners toward smarter, code-compliant, and sustainable material choices in Iowa.

Frequently Asked Questions

What are the environmental benefits of using sustainable building materials in Iowa?

Sustainable building materials significantly reduce environmental impact by minimizing waste and conserving resources. Options like recycled content products and locally sourced timber help lower carbon footprints and support local economies. Additionally, these materials often improve indoor air quality by using low-VOC finishes, which can lead to healthier living environments. By choosing sustainable materials, homeowners can also qualify for energy incentives, making eco-friendly choices both beneficial for the planet and financially advantageous.

How can homeowners ensure compliance with Iowa's building codes?

To ensure compliance with Iowa’s building codes, homeowners should familiarize themselves with local regulations regarding material performance, safety, and energy efficiency. Engaging with licensed contractors who understand these codes is crucial. Additionally, submitting detailed material specifications during the permitting process can help avoid costly retrofits. Regular communication with local building officials can also clarify any uncertainties, ensuring that all materials meet the required standards for safety and performance.

What are the advantages of using insulated concrete forms (ICF) for foundations in Iowa?

Insulated concrete forms (ICF) offer several advantages for foundations in Iowa, including superior energy efficiency and structural integrity. ICF provides continuous insulation, which minimizes heat loss and enhances comfort throughout the year. This type of foundation is also resistant to moisture and pests, making it ideal for Iowa’s climate. Additionally, ICF can reduce construction time due to its ease of installation, ultimately leading to cost savings for homeowners in the long run.

How do energy-efficient windows and doors contribute to overall home comfort?

Energy-efficient windows and doors play a crucial role in maintaining a comfortable indoor environment by minimizing heat transfer. Features such as low-emissivity (low-E) glass and multi-pane construction significantly reduce heat loss in winter and heat gain in summer. This not only enhances occupant comfort but also lowers energy bills by reducing the demand on heating and cooling systems. Proper installation further ensures airtight seals, preventing drafts and moisture intrusion, which can lead to mold growth.

What should homeowners consider when selecting roofing materials for Iowa homes?

When selecting roofing materials for Iowa homes, homeowners should consider factors such as durability, weather resistance, and energy efficiency. Materials like metal roofing offer excellent hail resistance and longevity, while asphalt shingles provide a cost-effective option with moderate durability. It’s also essential to evaluate the material’s ability to reflect solar heat, which can reduce cooling costs in summer. Additionally, local building codes and aesthetic preferences should guide the final choice to ensure compliance and satisfaction.

What are the long-term financial implications of investing in high-quality building materials?

Investing in high-quality building materials can lead to significant long-term financial benefits. While the initial costs may be higher, durable materials often require less maintenance and have longer lifespans, reducing replacement expenses over time. For example, fiber cement siding may cost more upfront but can last twice as long as cheaper alternatives, ultimately saving homeowners money. Additionally, energy-efficient materials can lower utility bills, further enhancing the overall return on investment.

How can homeowners effectively budget for home building materials in Iowa?

To effectively budget for home building materials in Iowa, homeowners should start by researching current market trends and material costs. Creating a detailed list of required materials and their estimated prices helps in setting a realistic budget. It’s also wise to include a contingency fund of 10-15% to account for unexpected expenses. Collaborating with experienced contractors can provide insights into labor costs and potential savings, ensuring a comprehensive financial plan that accommodates fluctuations in material prices.